About CirculaREEconomy

Rare-earth magnets, such as powerful Neodymium (NdFeB) magnets, are essential components in electric vehicles (EV) and can be found in powertrains, seat motors, speakers and many other systems. However, they are both difficult to recover and recycle and potentially vulnerable to global supply chains.

CREEM aims to transform this challenge into an opportunity.

Part funded by the Advanced Propulsion Centre (APC) and aligned with the UK Government’s DRIVE35 programme, the project is led by rare-earth recycling innovator Ionic Technologies. CREEM unites automotive OEMs, magnet specialists and recyclers to turn a hard-to-recycle challenge into a resilient, low-carbon UK supply chain.

Why it matters

Critical components, constrained supply

Powerful NdFeB (neodymium-iron-boron) magnets power EV traction motors, seat motors, speakers and more—but are difficult to recover and exposed to global supply risk.

Lower-carbon manufacturing

Early analysis by Ionic Technologies indicates refining secondary (recycled) material can reduce carbon impact by ~60% versus virgin routes.

Circularity at scale

A UK circular supply chain reduces biodiversity impacts from extracting primary materials, boosts the UK’s resource security, and can supports manufacturers’ net-zero goals.

“CirculaREEconomy is the next step in our collective mission to build a circular economy for rare-earth magnets—crucial to the green transition. Building on earlier projects, we and our consortium partners will work together to deliver an efficient, scalable and flexible long-loop supply chain—helping customers achieve circularity and net-zero targets, while meeting the highest safety standards for these powerful materials.”

How CREEM works

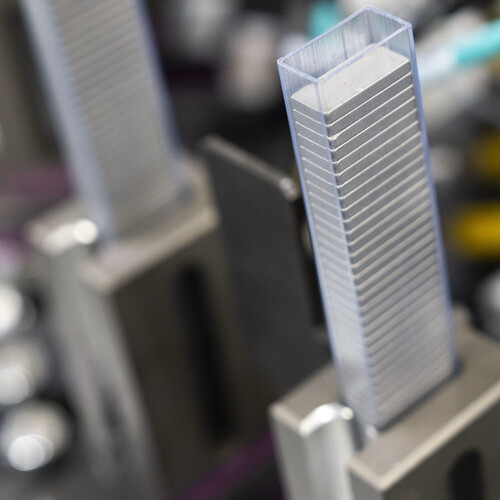

Targeted dismantling & liberation

EMR develops repeatable methods to access and separate magnets from motors and sub-assemblies—improving safety, yield and speed.

Advanced chemical recovery

Separated magnets are processed by Ionic Technologies back to constituent rare-earth oxides using specialist solvent and chemical steps.

Flexible remanufacture

Less Common Metals will alloy recovered oxides to enable manufacture of new magnets to the same quality of virgin materials, circularising materials from older EVs to power the next generation.

Measuring the environmental benefit

The British Geological Survey (BGS) will deliver material-flow analysis and a full Life Cycle Assessment (LCA) to quantify environmental benefits.

Project value

£11m (APC-funded R&D)

Create

The project will safeguard 15 jobs and create 4 new roles.

Focus

UK-wide circular supply chain for EV rare-earth magnets

Impact

~60% lower carbon vs virgin refining (early analysis)

Partners

CREEM is a partnership between rare-earth recycling innovator Ionic Technologies, global leader in sustainable materials, EMR, automotive manufacturers, Ford Technologies, Bentley Motors, Bamford Bus Company (Wrightbus), rare earth metals and magnet manufacturer, Less Common Metals and the British Geological Survey (BGS).